Pre-Engineered Buildings (PEB)

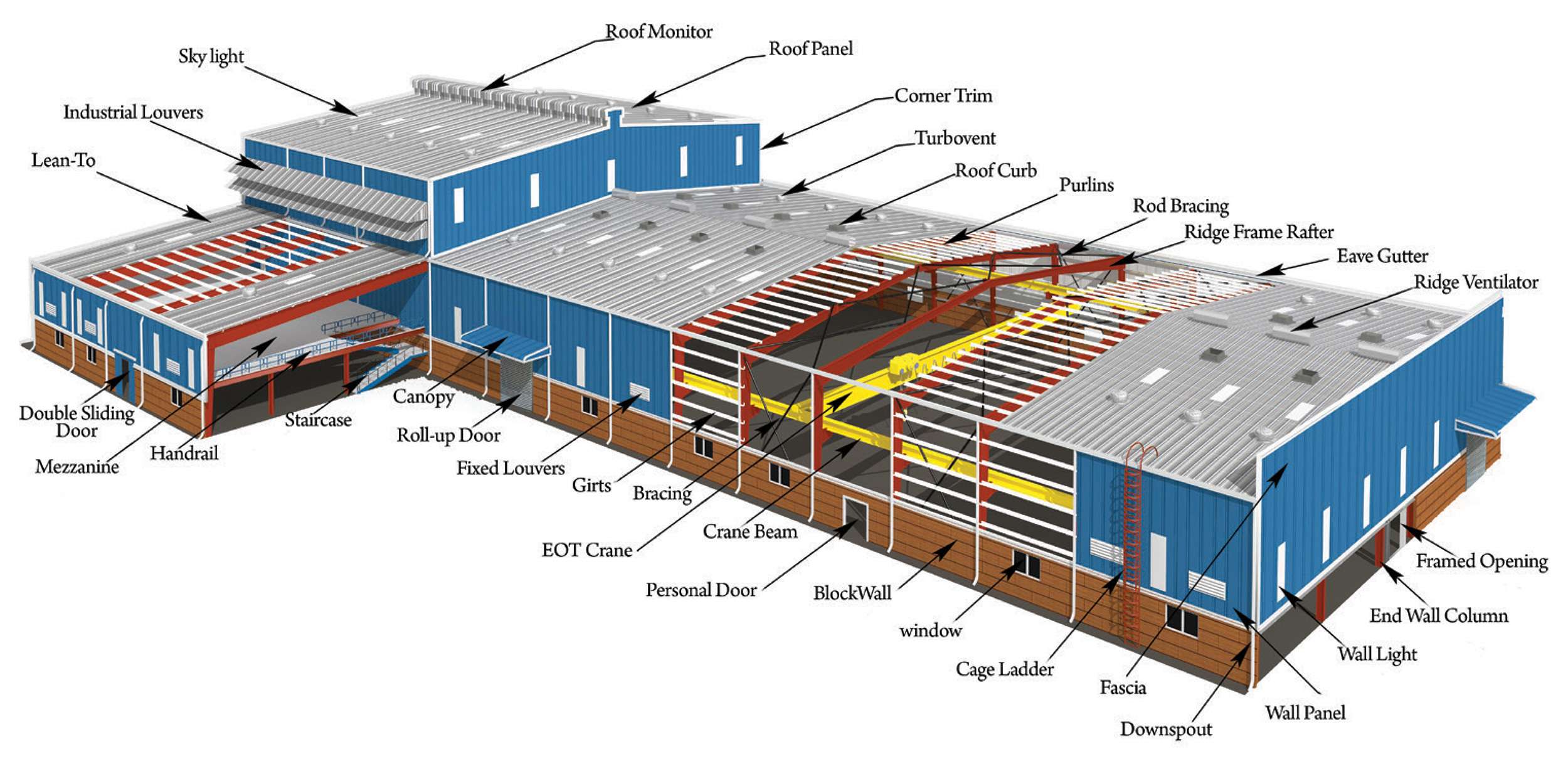

Pre-engineered Buildings provide exceptional design flexibility and significantly reduce construction time from design to completion. Delivered as a complete package with a steel framework, building accessories, and roof cladding, these structures require no on-site welding or fabrication. Assembly is straightforward, as components are bolted together according to specifications, offering a streamlined and efficient construction process.

Advantages

Pre- engineered buildings offer ultimate design flexibility and an extremely short construction time right from initial design to completion.

- Single Source Responsibility

- Faster Installation

- Overall Economical

- Practically Maintenance Free

- Flexibility In Expansion

- Factory Controlled Quality

- Earthquake Resistant

- Environmentally Friendly

The Most Common Applications Of Pre-Engineered Buildings Are:

Warehouses

Industrial Buildings

Factories

Sports Complex / Stadiums

Multi Stored Buildings

Cold Storages

Heavy Industries

Super Markets

Airport Structures

Workshops

Showrooms

Office Buildings

Distribution Centers

High Rise Structures

Primary Frame System

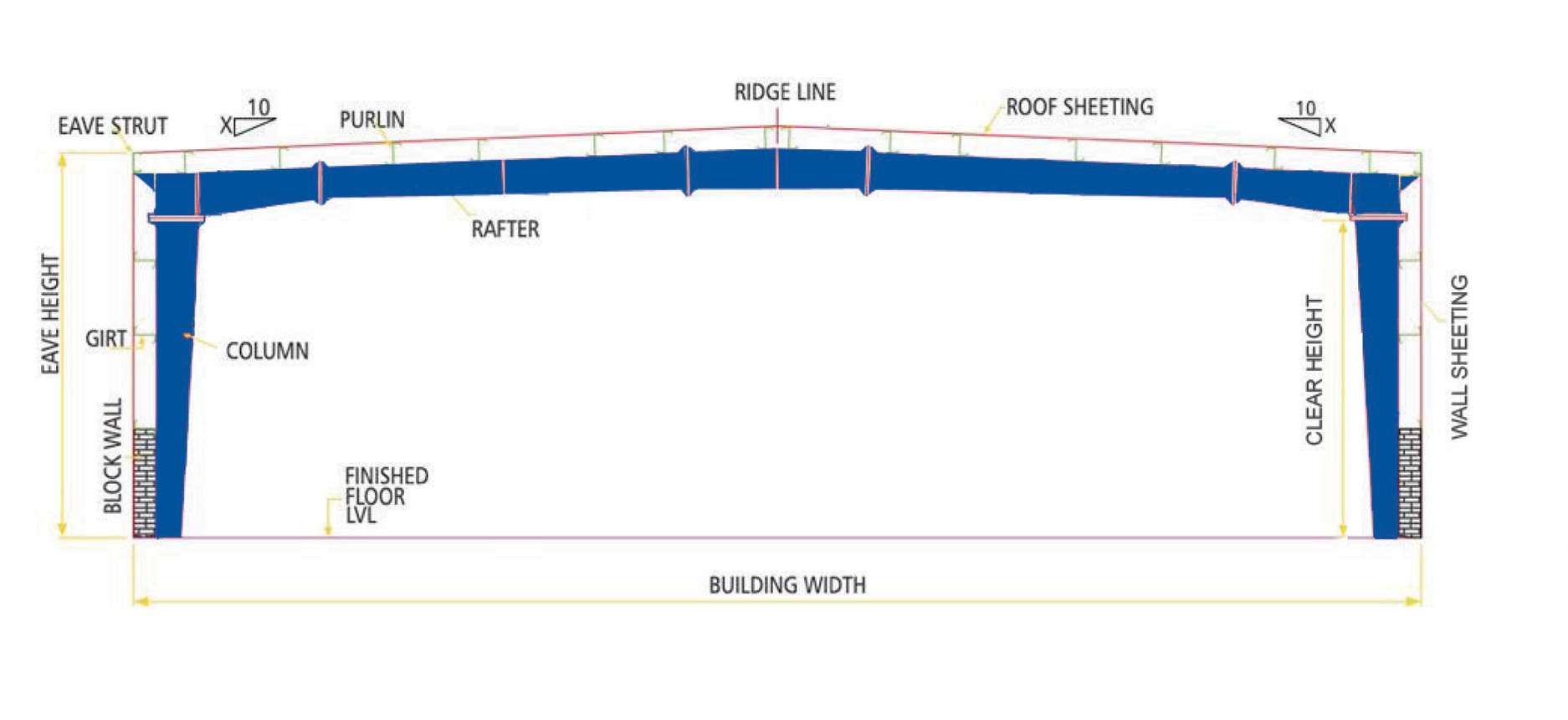

The primary frame system in pre-engineered buildings consists of the main steel structures, including columns, rafters, crane beams, mezzanine beams, and other key support components. These sections are manufactured using advanced technology and high-strength steel plates, ensuring durability and structural integrity.

Types of Main Frames

| FRAME SHAPE | FRAME TYPE | RECOMMONDED SPAN RANGE | REMARKS |

|---|---|---|---|

| Rigid Frame Clear Span | 20-40M | Suitable for ware houses, good owns, work shops industrial buildings having clear span requirement |

| Rigid Frame Clear Span-1 | 30-50M | Suitable for large span building without a valley gutter |

| Rigid Frame Clear Span-2 | 46-60M | For span greater than 48M it is economical to go for RFMS-2 frame than RFMS-1 |

| Rigid Frame Clear Span-3 | 50-75M | They are economical to go for RFMS-2 for span greater tha 72M |

| Rigid Frame Lean To | 6-18M | Suitable for extension of existing buildings |

| Single Sloped Building | 15-30M | Suitable for small spans with drainage facility to sigle side |

| Rigid Frame Multi Gable-1 | 50-100M | Economical tha RMFS-1 but with valley Gutter |

| Rigid Frame Multi Gable-2 | 80-120M | Economical tha RMFS-1 but with valley Gutter |

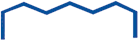

Secondary Members

Purlins, Girts, Eave struts, anchor bolts and brace rods are secondary members which are used for the support of roof and wall panels. Purlins are used on roof, girts are used on wall and Eave struts are used at intersection of roof and wall panels.

C&z Sections

- Thickness Range – 1.5 mm to 3.0 mm

- Profile Width – 200 mm to 300 mm

- Material Finish – Pre- Galvanized (120 GSM/180 GSM/275 GSM)

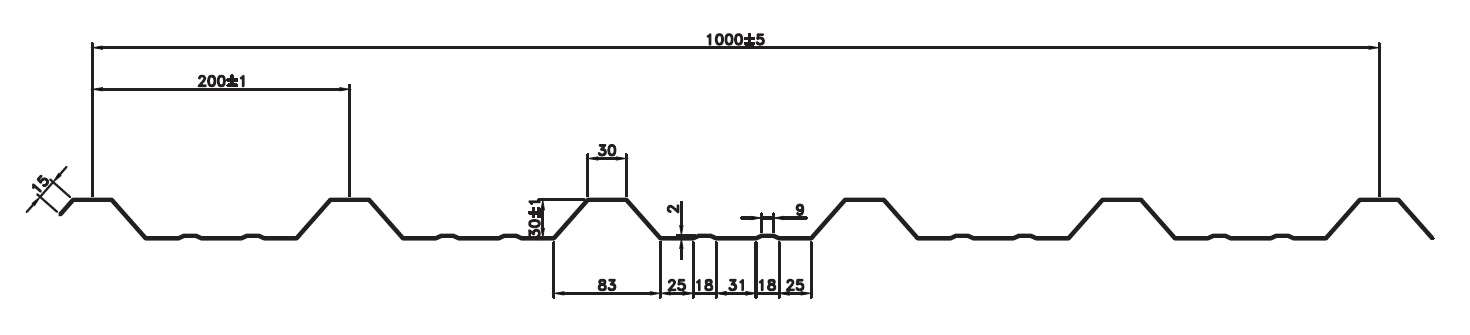

Roof & Wall Sheeting

Roof and Wall panels used are profiled steel sheets and are produced from steel coils which are hot dipped galvanized, and with a minimum of AZ150 zinc-aluminum coating on it.

Roof & Wall Sheeting

- Tensile Strength – 550 MPA

- Thickness Range – 0.3 mm to 0.8 mm

- Effective Width – 1000 mm

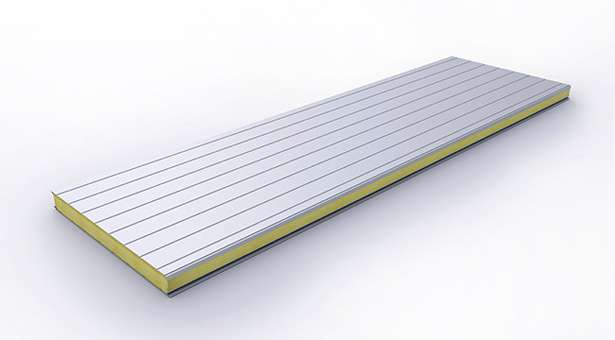

Greenstone Sandwich Panel

Paramount sandwich panels offer significant savings on equipment and energy costs by effectively regulating the building’s climate, whether for heating or cooling. Available in thicknesses from 30 mm to 120 mm, these panels are highly durable and resistant to extreme weather conditions, making them a reliable choice for long-lasting performance.

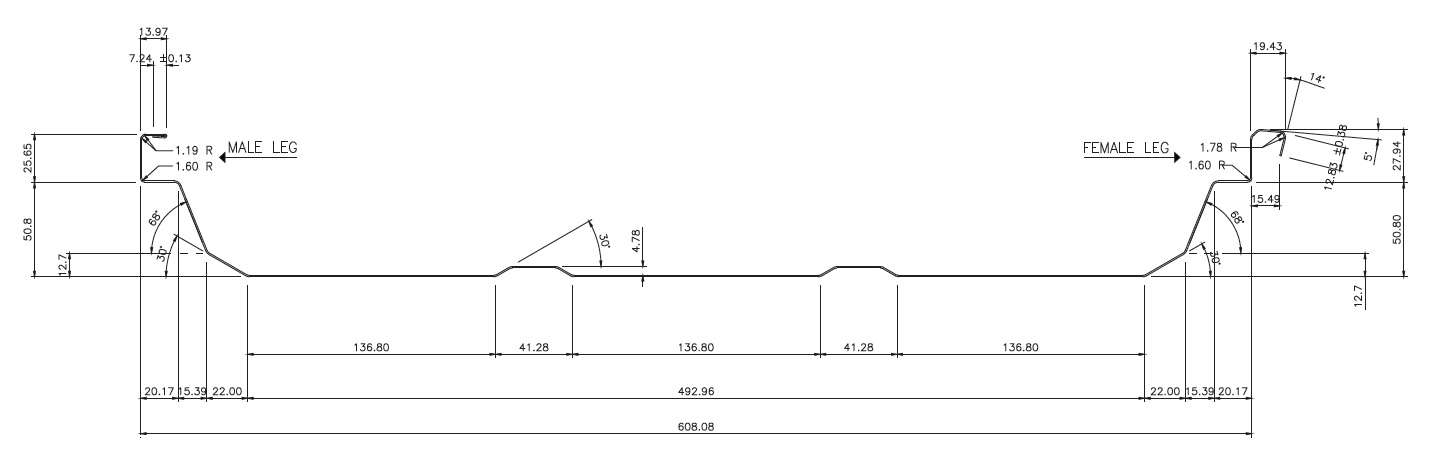

Greenstone Standing Seam Roof System

Standing Seam Roof Sheeting

- Tensile Strength – 345 MPA

- Thickness Range – 0.5 mm to 0.6 mm

- Effective Width – 608.08 mm

Standard Sheeting Colors

Greenstone Deck Sheeting

- Thickness Range – 0.8 mm to 1.2 mm

- Effective Width – 972 mm

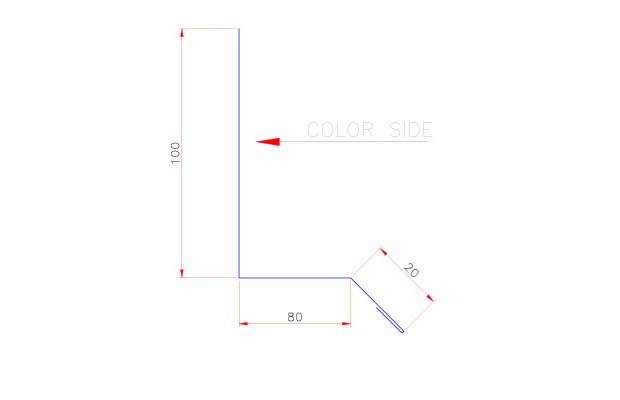

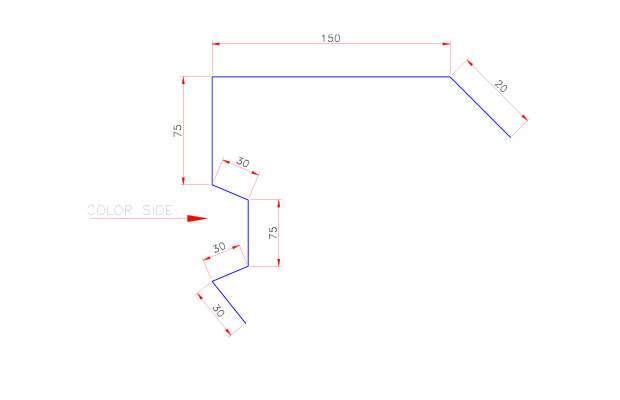

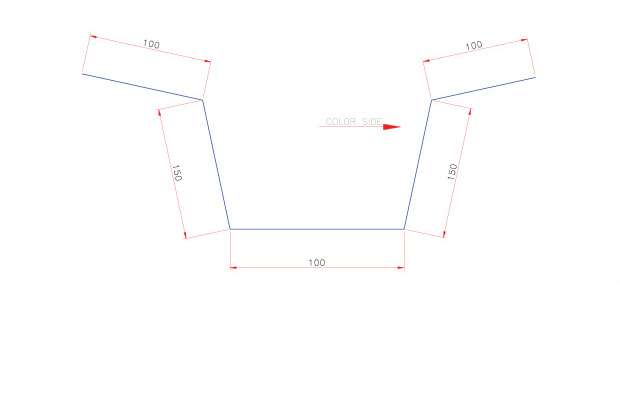

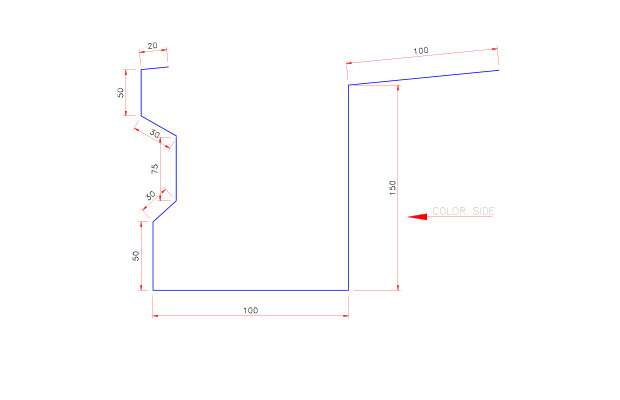

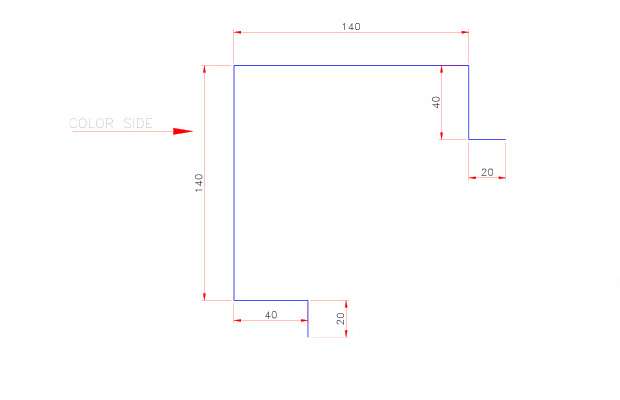

Trims / Flashings

Standard Flashing

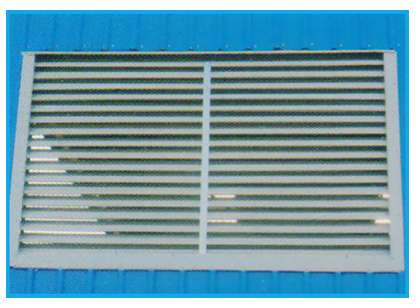

PEB Accessories

Fixed Louvers

Greenstone’s standard louvers are 1m(W) X 1m(H) & 2m(W) X 1m(H). Non- standard sizes can also be provided on request

Sky Lights and Wall Lights

Greenstone’s standard sky lights/wall lights are 2 mm thick Polycarbonate sheets with size 1.0 M X 3.0 M. Non-standard lengths are available on request.

Turbo Ventilators

Greenstone’s standard comes in two variations either in FRP or Polycarbonate with 600 mm dia.

Ridge Ventilators

Greenstone's standard ridge ventilators are of 0.3 M throat width and can be supplied either continuous or in modules of 3.0 M length.

Roof Curb

Fiberglass roof curbs will be provided power ventilators at the ridge are required. Roof curbs are also supplied, if requested by customers, to support roof mounted fans or other equipment.

Sliding Doors

Standard Single or Double sliding doors are of sizes varying from 3.0M X 3.0M to 5.0M X 5.0M. Paramount can also offer any other bigger size if required by the customers.

Insulation

We supply different type of insulations as mentioned below based on clients requirement such as Fibre glass Insulation, Rock Wool Insulation, XLPE Insulation & Fibre glass Insulation